You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Absolutely Gutted!!

- Thread starter martings

- Start date

the grim reeper

A2OC Donor

Its all starting to take shape, when its all done someone should get all the photos and make a slide show

Cheers Phil

Cheers Phil

a bit of an update again

so the new panel is clamped on

door gap checked

boot bolted back on and gap checked

light gap checked

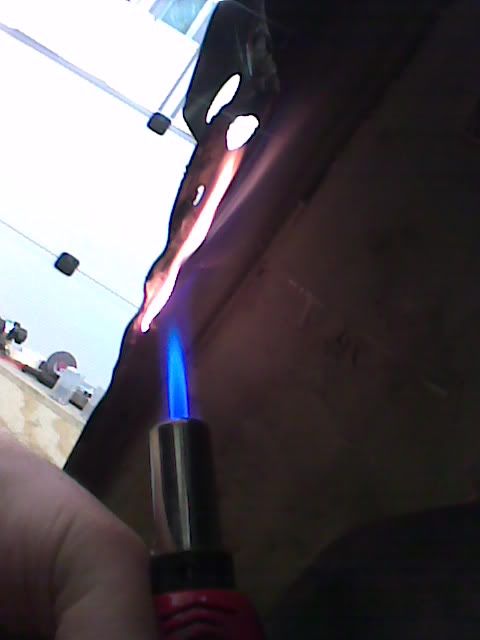

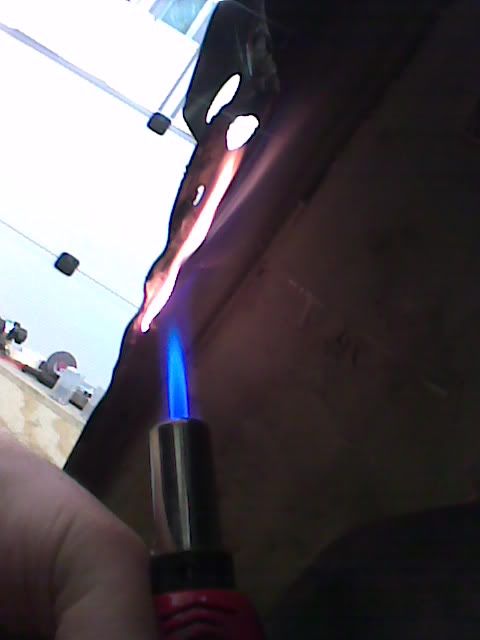

inner wing was still in slightly so heated up and planished into the right place

FIIIIIRRRRRRRREEEEEEEEEEE!!!!!! lol

oh and whilst it was up in the air i notised the bump stop is a bit worn, so you might want to check the others and change them if ness

anyway, once i knew the panel was in the right place i started chopping, basically i cut through both overlapped panels and you get the below pic (then i will have a plate behind, you will see later on in the process)

so the new panel is clamped on

door gap checked

boot bolted back on and gap checked

light gap checked

inner wing was still in slightly so heated up and planished into the right place

FIIIIIRRRRRRRREEEEEEEEEEE!!!!!! lol

oh and whilst it was up in the air i notised the bump stop is a bit worn, so you might want to check the others and change them if ness

anyway, once i knew the panel was in the right place i started chopping, basically i cut through both overlapped panels and you get the below pic (then i will have a plate behind, you will see later on in the process)

1/4 taken back off and before i do anything to that i did a bit of welding so out comes the big hoover and welding blanket

this was a small split and i have cut it slightly thicker so i can weld it propperly, and its double skinned so no need for a plate

welded and ground down

and i welded the plate in whilst the welder was out, and its not the best looking weld in the work i will admit, but it will defo do the job (very hard to weld ally with a mig welder, much easier with a tig but audi wont let you do that, its not in there approved ways )

)

so thats your lot for today, 1/4 will be fitted tomorrow as it is cleaned up and i have allready made the plates for it

this was a small split and i have cut it slightly thicker so i can weld it propperly, and its double skinned so no need for a plate

welded and ground down

and i welded the plate in whilst the welder was out, and its not the best looking weld in the work i will admit, but it will defo do the job (very hard to weld ally with a mig welder, much easier with a tig but audi wont let you do that, its not in there approved ways

so thats your lot for today, 1/4 will be fitted tomorrow as it is cleaned up and i have allready made the plates for it

i dont know if it is on the jobcard, and i have to say that i havent seen it myself, allthough the lower part of the bootlid is made of plastic so i doubt it would have dented, i will look into it for you if i remember lol.

heres some more progress pics

new panel is drilled and countersunk along the bootlid edge and the upper part of the lamp panel, due to not being able to get to both sides of the panel with the rivvet tool.

then the same is done with the joining panel on the car so the panel fits flush and so the rivvets sit as flush as possible

then i had to measure and drill holes (panels dont come with any pre drilled holes) where the bracket for the wheel arches go, as these have riv nuts in(picture shows riv nuts in place)

cleaned up scotched and etch primed

prepped and primed new panel

loadsa bond

plates bonded in ready for welding

heres some more progress pics

new panel is drilled and countersunk along the bootlid edge and the upper part of the lamp panel, due to not being able to get to both sides of the panel with the rivvet tool.

then the same is done with the joining panel on the car so the panel fits flush and so the rivvets sit as flush as possible

then i had to measure and drill holes (panels dont come with any pre drilled holes) where the bracket for the wheel arches go, as these have riv nuts in(picture shows riv nuts in place)

cleaned up scotched and etch primed

prepped and primed new panel

loadsa bond

plates bonded in ready for welding

panel placed on and rivvets put in place(looks like hellraiser lol)

picture of the panel fully rivveted on

rivvets around the window

rivvets and riv nuts around the wheel arch

around the lamp panel

and these are the ones that are sunk into the metal, they wil need sanding down slightly

picture of the panel fully rivveted on

rivvets around the window

rivvets and riv nuts around the wheel arch

around the lamp panel

and these are the ones that are sunk into the metal, they wil need sanding down slightly

another update

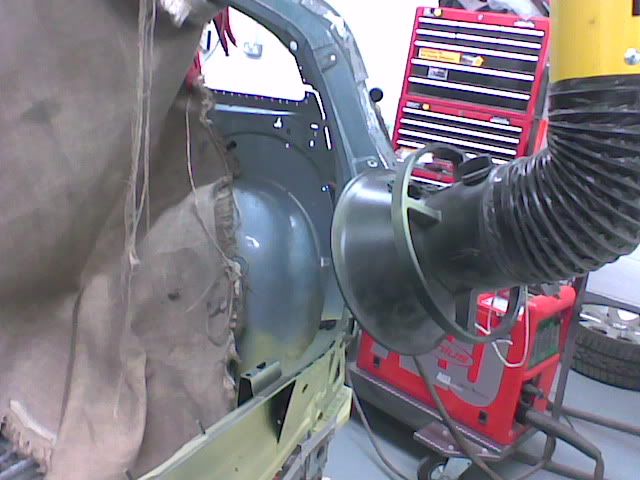

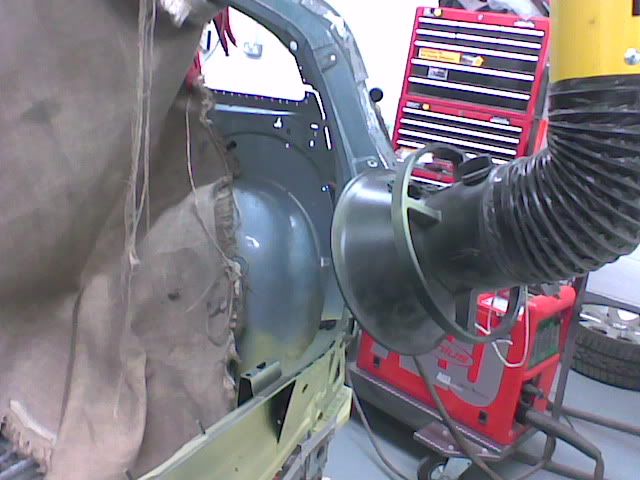

car sheeted up for welding

gap shown with plate showing underneith

welded and grounded down the 3 joints

and a tiny bit of filler to get rid of a few small marks

and the filler is rubbed down now, i am just waiting for 100 rivvets!!!!! as thats how many hold the other back panel in place!!!!

hopefully they will be here tomorrow, as audi dont keep tem in stock, well not that many anyway lol

car sheeted up for welding

gap shown with plate showing underneith

welded and grounded down the 3 joints

and a tiny bit of filler to get rid of a few small marks

and the filler is rubbed down now, i am just waiting for 100 rivvets!!!!! as thats how many hold the other back panel in place!!!!

hopefully they will be here tomorrow, as audi dont keep tem in stock, well not that many anyway lol

John H

Member

Now I see why Audi was so eager to stop making our car. So much rivets and glue!

Indeed, and the more I see of this thread, the more I understand why Audi has not followed on with another A2. Most car production is done by robots these days, which allows economy of manufacture, and hence higher profit margins. From the pictures and descriptions in the thread it is obvious that the A2 must have been VERY labour intensive to manufacture (highly skilled labour at that) so I now understand why it was so expensive, and was probably never very profitable. Fascinating thread, and highly educational too.